Electroplating & Surface Treatment Plants

Overview

Metal Coat Industry is a trusted electroplating and surface treatment plant manufacturer and exporter from India, specializing in the design and supply of manual, semi-automatic, and automatic coating plants for fasteners, automotive parts, and industrial components. Our plants are engineered for consistent coating quality, process reliability, and environmental compliance, suitable for Indian and international markets.

We provide complete turnkey surface treatment solutions, including process design, equipment manufacturing, fabrication, automation, installation, and commissioning.

Our Electroplating & Coating Plant Solutions

1) Zinc Electroplating Plants

Designed for corrosion protection of fasteners and industrial components with controlled thickness and uniform finish.

Key Features

- Barrel and rack plating options

- Acid and alkaline zinc processes

- Manual, semi-automatic, or automatic lines

- Rectifier-based DC power supply

- Consistent coating thickness and surface finish

2) Nickel Electroplating Plants

Suitable for decorative and functional applications requiring wear resistance and improved surface properties.

Key Features

- Rack or barrel plating configuration

- Controlled bath chemistry

- Uniform deposition and adhesion

- Automotive and industrial applications

Get a Quote

Need more help?

+91 9370616661

office@metalcoatindustry.in

Balaji Industrial Park, E-26, Tondare, Taloja, Navi Mumbai, Maharashtra 410208, India

3) Electropolishing Plants

We design electropolishing plants for stainless steel components to improve surface finish, corrosion resistance, and cleanliness.

Key Features

- Controlled anodic dissolution process

- Improved surface smoothness and brightness

- Reduced surface contamination

- Suitable for SS fasteners, fittings, and precision components

4) Hard Chrome Plating Plants

Our hard chrome plating plants are designed for components requiring high wear resistance and dimensional accuracy.

Key Features

- Heavy-duty DC rectifiers

- Controlled thickness build-up

- Suitable for shafts, rollers, and industrial components

- Optional automation for repeatability

5) Phosphate & Passivation Lines

Used as pre-treatment or post-treatment to enhance corrosion resistance and coating adhesion.

Key Features

- Zinc phosphate / manganese phosphate systems

- Trivalent and hexavalent passivation options

- Improved corrosion resistance

- Suitable for fasteners and fabricated parts

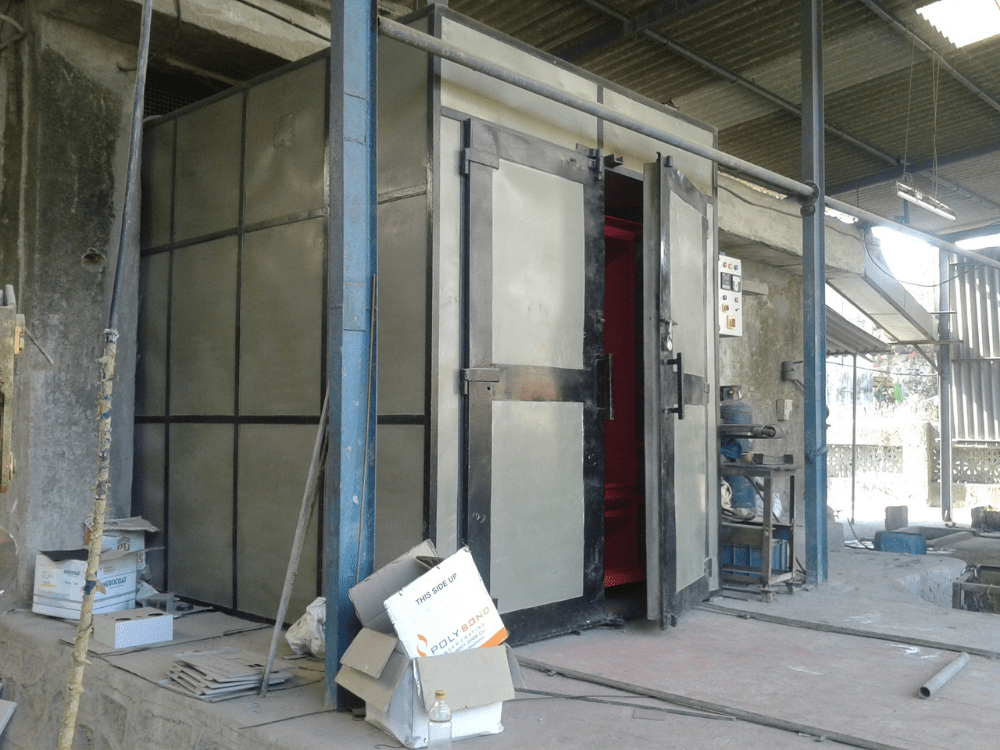

6) Powder Coating Plants

We supply powder coating plants for decorative and protective finishes on metal components.

Key Features

- Pretreatment lines

- Powder spray booths

- Curing ovens

- Manual and automatic configurations

7) CED (Cathodic Electro Deposition) Coating Plants

Designed for high-corrosion-resistance applications, especially in automotive and industrial sectors.

Key Features

- Uniform coating even in complex geometries

- High throw power

- Excellent corrosion protection

- Fully automated process lines

8) PTFE / Fluoropolymer Coating Plants

We design PTFE and fluoropolymer coating plants for applications requiring low friction, chemical resistance, and non-stick properties.

Key Features

- Spray and dip coating options

- Controlled curing ovens

- Suitable for industrial and specialty components

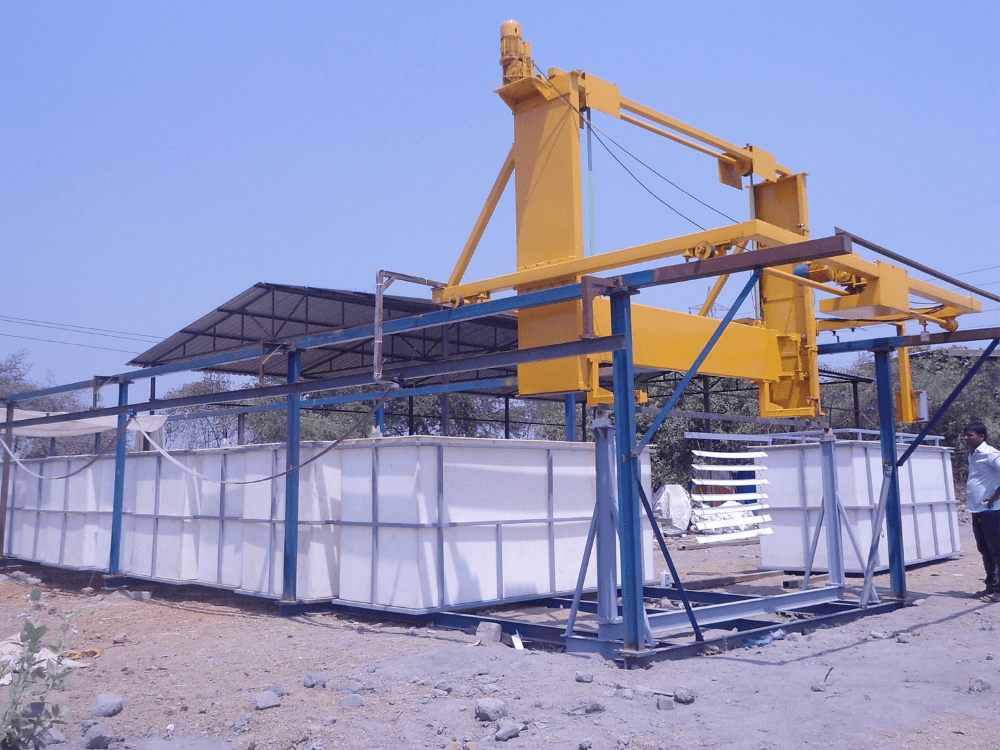

9) Process Tanks

Key Electroplating & Coating Equipment

- PP, PPFRP, MS rubber-lined construction

- Chemical-resistant design

- Long service life

10) Rectifiers & Electrical Systems

- High-efficiency DC rectifiers

- Stable current and voltage control

- Designed for continuous industrial duty

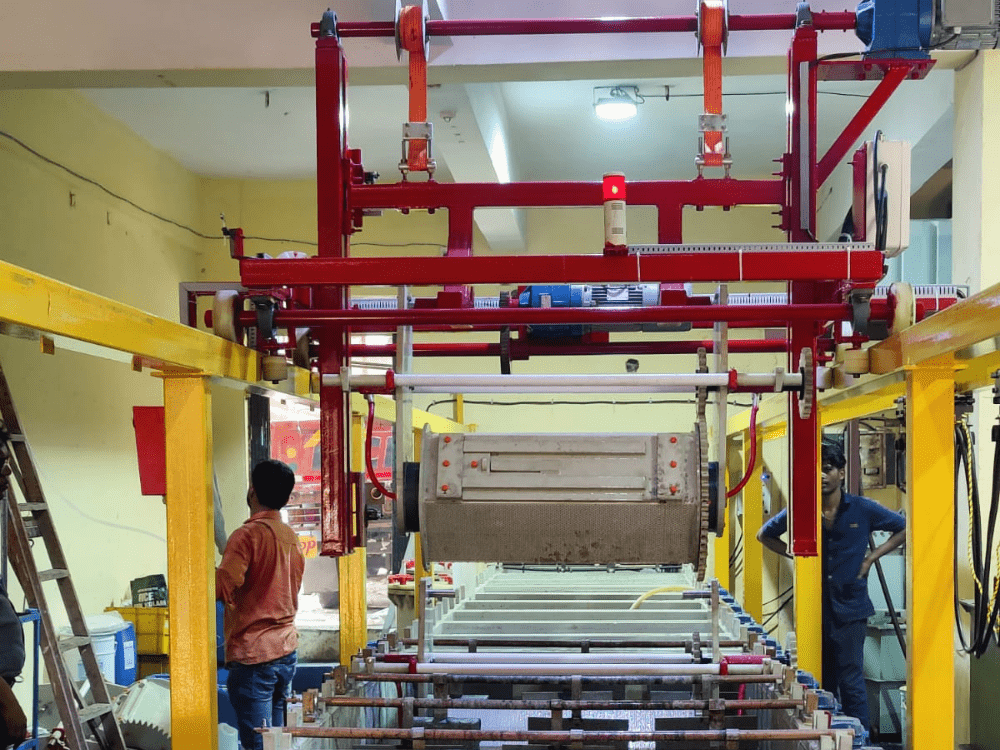

11) Material Handling Systems

- Manual and motorized hoists

- Barrel handling systems

- Jigs, fixtures, and racks

12) Acid Fume Scrubber Installed to control:

- Acid fumes and vapors

- Operator exposure

- Environmental emissions

13) Effluent Treatment Plant (ETP)

Designed to treat electroplating and coating effluents.

Functions

- Heavy metal removal

- pH correction

- Sludge separation and handling

- Compliance with pollution control norms

Automation & Process Control

Electroplating and coating plants can be supplied with PLC or PLC–SCADA based automation systems for:

- Process sequencing

- Current, voltage, and time control

- Production monitoring

- Safety interlocks and alarms

Automation ensures repeatable quality, reduced manpower, and export-ready operation.

Fabrication & Manufacturing Capability

We have in-house fabrication capability for:

- Process tanks and structures

- Platforms and supports

- Ducting, scrubbers, and enclosures

Fabrication is carried out as part of complete surface treatment plant manufacturing, ensuring dimensional accuracy and quality control.

Why Choose Our Electroplating & Coating Plants

- Trusted surface treatment plant manufacturer in India

- Experience in export-oriented turnkey projects

- Wide range of electroplating and coating technologies

- Automation-ready and energy-efficient designs

- End-to-end support from design to commissioning

Applications

Our electroplating and coating plants are used for:

- Fasteners and hardware components

- Automotive and engineering parts

- Industrial and fabricated components

- Decorative and functional coatings

Metal Coat Industry is a reliable electroplating and surface treatment plant manufacturer and exporter from India, offering zinc, nickel, electropolishing, hard chrome, powder coating, CED coating, PTFE coating plants, along with automation, pollution control, and turnkey solutions worldwide.